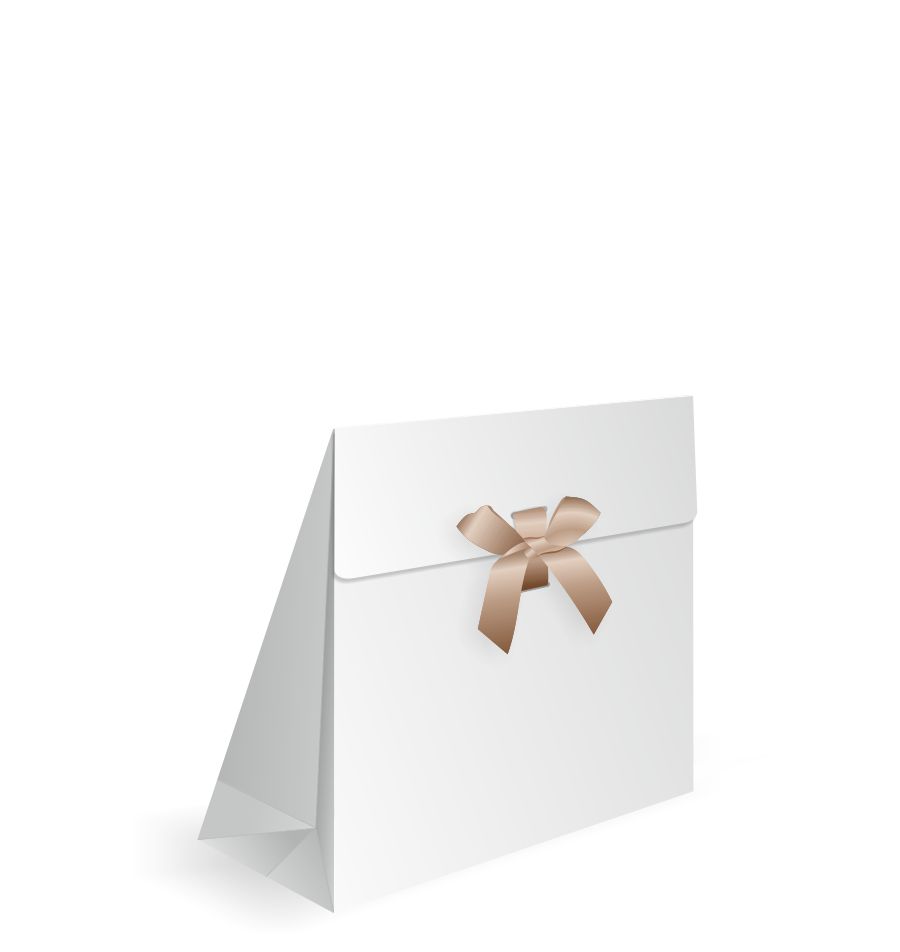

Artistic Flap Bag

CUSTOM DESIGN FLAP PAPER BAGS IN VARIABLE STYLES

Product styles / Artistic flap bag

Superior impression and unlimited creativity

As a cherished result of nPack’s thirst for innovation and of profound industry knowledge, these custom designed bags became one of our bestsellers. The flap element allows for a large extent of freedom during the product development of these highly customisable paper bags. Due to this feature, these remarkable and exclusive bags are the top-notch choice for event memorabilia, corporate luxury gifts and more.

CUSTOMISATION OPTIONS

Bag style options

FLAP ATTACHMENT

Seamless or constructed flap

FLAP CAPACITY

Capacity and non-capacity flap

PAPER COLOURS

Single colour or two colours

HANDLE STYLE

Die-cut handle, ribbon loop,

single rope/ribbon, no handle

CLOSURE STYLE

Velcro, tuck-lock,

threaded ribbon tie, adhesive

FLAP SHAPE

Regular or custom

Detailed info below:

Bag Anatomy; Design Upgrades

MINIMUM ORDER – 100 PCS

Sizes, materials & finishes

SIZES

Variety of stock cutters or custom size by request

PREMIUM PAPERS

White or colour-dyed papers made in Europe, smooth or textured in different patterns

PRINTING OPTIONS

CMYK or Pantone printing for exact colour match

LUXURY FINISHES

Foil blocking, foil embossing, foil debossing, blind embossing, blind debossing or spot UV

COATING

Matt, gloss or soft touch lamination

1300 +

STOCK SIZE CUTTERS

AVAILABLE

60 +

DESIGN ELEMENTS READY FOR

PRODUCTION

100 +

PREMIUM PAPERS IN

PRODUCTION

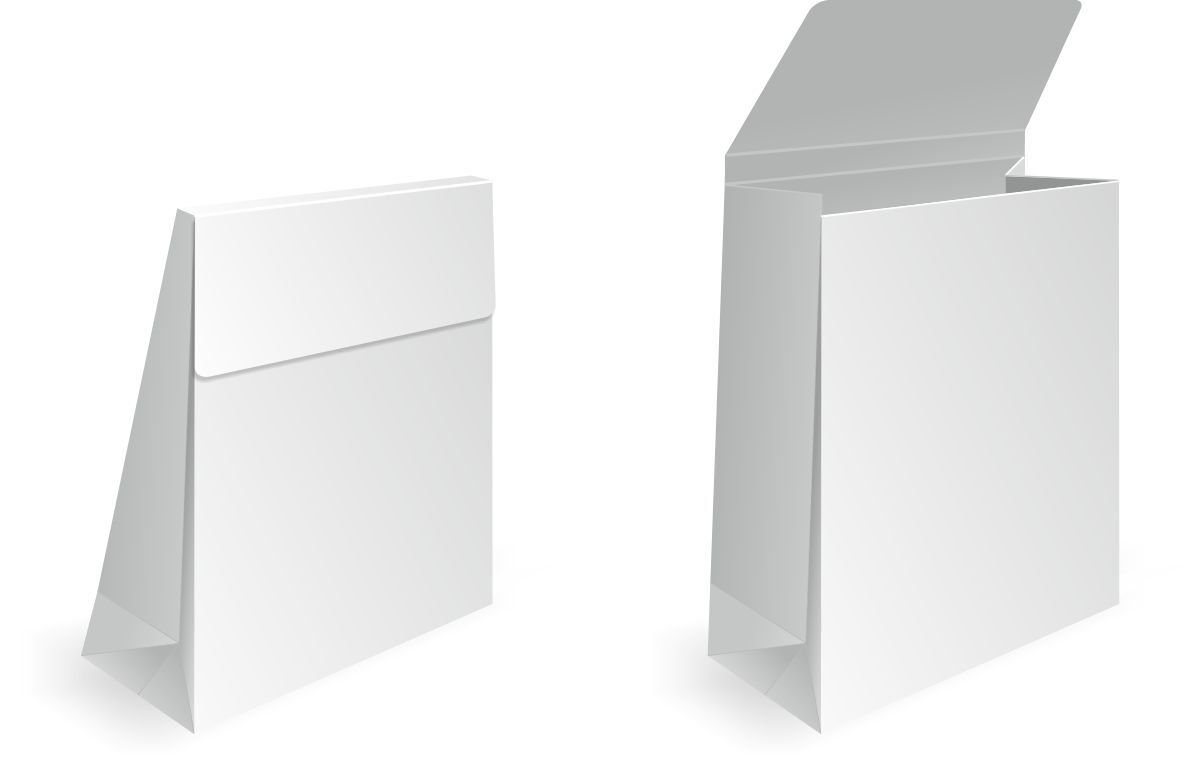

Structural elements

The basic, constant elements of this bag style are the rectangular bag body and the hinged flap. The flap may have different custom design features, all of which have some advantages for the bag’s purpose and functionality.

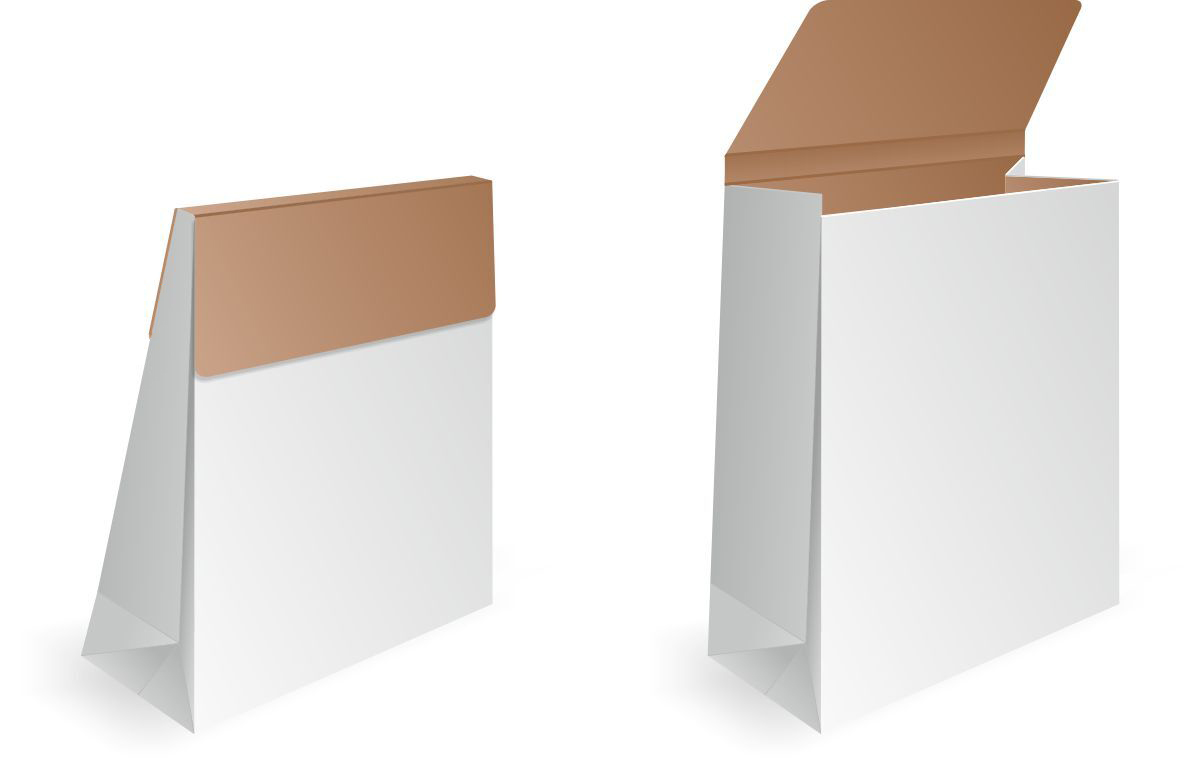

Flap Attachment

Depending on the method of connecting to the bag body, the flap can be seamless or constructed.

extending from one of the bag’s sides, not glued

attached to the bag using a glueing seam

Flap Capacity

The upper part of the flap can have two creases rather than one, which creates a small capacity at the top of the bag.

The flap capacity is a key feature that should be considered during the design concept development. Also important are the reinforcements on the body and the flap.

Bag Body Materials

The bag body is made from paper or paperboard. The material thickness is usually around 200 to 300 g/sq.m. Sometimes, we use duplex (2-layered) paper with different coloured sides.

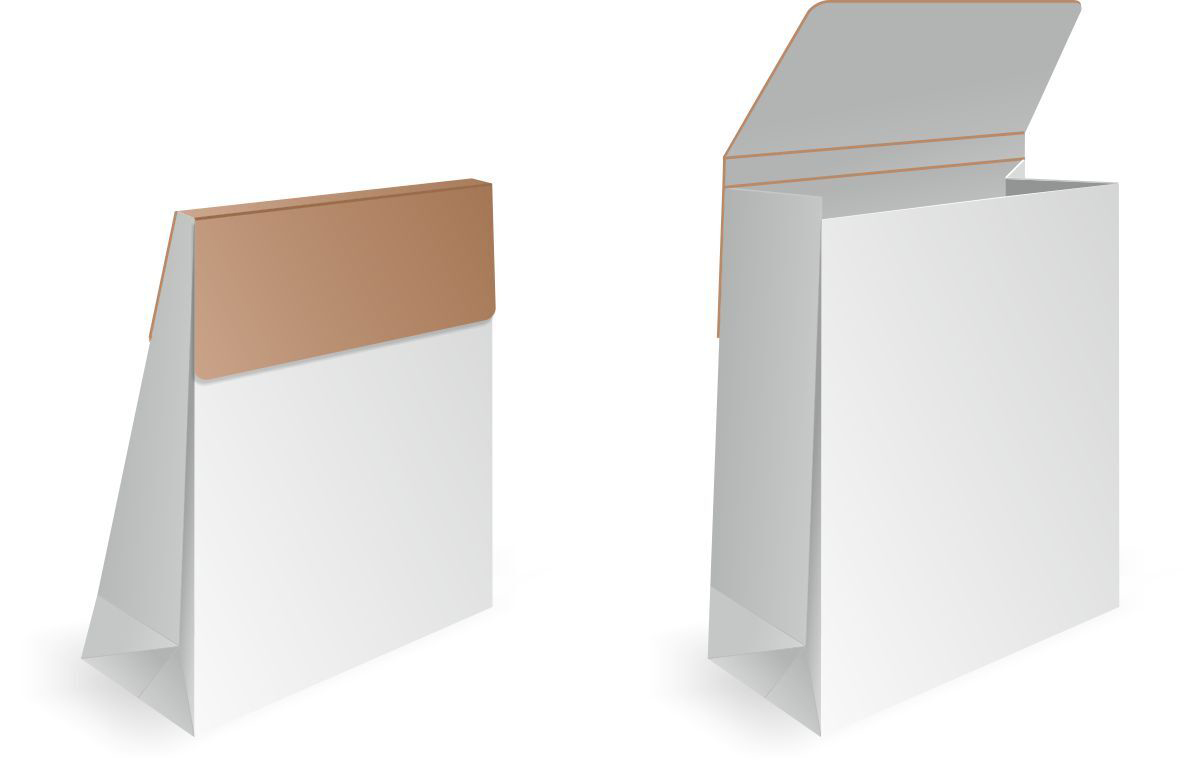

Flap Materials

The material of the seamless flap is an extension of the bag body, hence it’s the same as the bag body.

The material of the constructed flap can be different from the bag’s body material, often in a contrasting colour.

Bag Body Reinforcement

To increase the bag’s strength and reliability, we glue permanent reinforcing layers. Always present, is the reinforcement on the inside of the bag’s bottom.

The reinforcements at the upper ends of the bag’s body are optional. All reinforcements have a thickness of at least 350 g/sq.m and typically use the colour and texture of the material of the bag’s inner side.

Flap Reinforcement

The reinforcement of the flap capacity inside is strongly recommended.

Reinforcing the flap’s front panel on the inside is optional. The front reinforcement is not only present for strength and reliability, it is a designer’s tool to add visual appeal by using different colours and textures. For the flap reinforcements, we typically use thick paperboard.

The flap capacity is a key feature that should be considered during the design concept development. Also important are the reinforcements on the body and the flap.

Bag Body Materials

The bag body is made from paper or paperboard. The material thickness is usually around 200 to 300 g/sq.m. Sometimes, we use duplex (2-layered) paper with different coloured sides.

Flap Materials

The material of the seamless flap is an extension of the bag body, hence it’s the same as the bag body.

The material of the constructed flap can be different from the bag’s body material, often in a contrasting colour.

Bag Body Reinforcement

To increase the bag’s strength and reliability, we glue permanent reinforcing layers. Always present, is the reinforcement on the inside of the bag’s bottom.

The reinforcements at the upper ends of the bag’s body are optional. All reinforcements have a thickness of at least 350 g/sq.m and typically use the colour and texture of the material of the bag’s inner side.

Flap Reinforcement

The reinforcement of the flap capacity inside is strongly recommended.

Reinforcing the flap’s front panel on the inside is optional. The front reinforcement is not only present for strength and reliability, it is a designer’s tool to add visual appeal by using different colours and textures. For the flap reinforcements, we typically use thick paperboard.

Make it remarkable

There are numerous different ways to create a purpose for the bag’s elements. The colour combinations have no limit. What’s more, we can customise the flap and the functionality of the paper bag by changing the handle style, the flap shape and the means of closure.

Paper Colours & Textures

At this point, after years of technological refinement of this bag style, we have achieved unprecedented freedom of design.

The full-width flap bag, especially when it is constructed, has an unparalleled number of variants of paper combinations. Both the flap and body can differ in material. In addition, we can use different coloured reinforcement layers from premium papers – plain or embossed. Also important, the bag body can have 2-sided, duplex material, made again from premium papers, meaning that the whole inside is different from the outside.

| Bag body: | 2 colours |

| Flap: | 1 colour |

| Bag body: | 1 colour |

| Flap: | 2 colours |

| Bag body: | 1 colour |

| Flap: | 1 colour |

| Bag body: | 2 colours |

| Flap: | 2 colours |

Above, some of the possible options are shown for inspiration.

Handle Style

In addition to the visual impact, the choice of handle presence and type should be in accordance with the weight that the bag is expected to carry.

| Customisable grip hole shape & size |

| Suitable for 100% recyclable paper bags |

| Good for heavy products |

Die-Cut Handle

The flap capacity is optional for this handle style. When present, it is limited to 15mm.

The flap reinforcement makes the bag more exclusive. The presence of a flap reinforcement depends on the bag size and the intended load. It is recommended for large bags and heavy weights.

The applicable flap closure styles are velcro and tuck-lock.

There are no limitations considering the flap outline. The minimum flap height is determined by the technological requirements for the distance between the grip holes and the creases.

| Unlimited ribbon styles |

| Customisable ribbon length |

| Good for lightweight products |

Ribbon Loop

This handle style is only applicable to non-capacity flaps.

It is not necessary to use flap reinforcement unless the design includes a premium appearance with extra colour or texture on the inside.

The ribbon handle itself is the means of closure. No other flap closure styles are applicable.

There are no limitations considering the flap outline. The flap height is determined by the client’s requirements, considering that the ribbon slot reduces the useful volume of the bag.

Single Rope Or Ribbon

This handle style is only applicable to a flap capacity of at least 15 mm.

Depending on the bag body paper thickness and the bag size, adding a flap reinforcement should be considered for strength and a more-luxury feel. Тhe capacity reinforcement is a key element.

All flap closure styles are applicable, apart from the tuck-lock type.

There are no limitations considering the flap outline and height.

| Тypically used for disposable packaging |

| Suitable for 100% recyclable paper bags |

| Good for lightweight products |

The presence of a flap capacity is optional for this bag style.

No Handle

It is not necessary to use a flap reinforcement unless to add colour and texture to the inside for a more upscale appearance.

All flap closure styles are applicable. A tear strip and perforation plus double peel-and-seal adhesive stripes turn this bag style into an e-commerce paper mailer bag.

There are no limits to the flap outline. The flap height is determined by the technological requirements for the distance between the grip holes and the creases.

| Customisable grip hole shape & size |

| Suitable for 100% recyclable paper bags |

| Good for heavy products |

Die-Cut Handle

The flap capacity is optional for this handle style. When present, it is limited to 15mm.

The flap reinforcement makes the bag more exclusive. The presence of a flap reinforcement depends on the bag size and the intended load. It is recommended for large bags and heavy weights.

The applicable flap closure styles are velcro and tuck-lock.

There are no limitations considering the flap outline. The minimum flap height is determined by the technological requirements for the distance between the grip holes and the creases.

| Unlimited ribbon styles |

| Customisable ribbon length |

| Good for lightweight products |

Ribbon Loop

This handle style is only applicable to non-capacity flaps.

It is not necessary to use flap reinforcement unless the design includes a premium appearance with extra colour or texture on the inside.

The ribbon handle itself is the means of closure. No other flap closure styles are applicable.

There are no limitations considering the flap outline. The flap height is determined by the client’s requirements, considering that the ribbon slot reduces the useful volume of the bag.

Single Rope Or Ribbon

This handle style is only applicable to a flap capacity of at least 15 mm.

Depending on the bag body paper thickness and the bag size, adding a flap reinforcement should be considered for strength and a more-luxury feel. Тhe capacity reinforcement is a key element.

All flap closure styles are applicable, apart from the tuck-lock type.

There are no limitations considering the flap outline and height.

| Тypically used for disposable packaging |

| Suitable for 100% recyclable paper bags |

| Good for lightweight products |

The presence of a flap capacity is optional for this bag style.

No Handle

It is not necessary to use a flap reinforcement unless to add colour and texture to the inside for a more upscale appearance.

All flap closure styles are applicable. A tear strip and perforation plus double peel-and-seal adhesive stripes turn this bag style into an e-commerce paper mailer bag.

There are no limits to the flap outline. The flap height is determined by the technological requirements for the distance between the grip holes and the creases.

Closure Style

The means of closure is a significant feature in this inventive bag design. Not only Its choice affects the visual appeal of the packaging, but it also changes its functionality and purpose.

| Variable velcro shape, colour & strength |

| Doesn’t interfere with the bag’s artwork |

| Suitable for repeated opening and closing |

Velcro

The presence of a flap capacity is optional for this closure style.

The flap reinforcement makes the bag more luxurious. The presence of a flap reinforcement depends on the bag size and the intended load. It is recommended for large bags and heavy weights.

This closure is applicable for all handle styles, apart from the ribbon loop style.

There are no limitations considering the flap outline and height.

| Variable shape of the locking element |

| Suitable for 100% recyclable paper bags |

| Suitable for repeated opening and closing |

Tuck-Lock

This closure style is usually applied to non-capacity flaps. Only a limited variety of locking element shapes can be used with capacity flaps.

The tuck-lock requires flexibility of the flap panel. It’s typically used on flaps with no flap reinforcement.

The tuck-lock combines beautifully with the die-cut handle style, or with a flap bag with no handle.

Any kind of flap outline and height is applicable. Small-size bags are more suitable for this closing style.

| Satin and grosgrain ribbon styles |

| Customisable ribbon length |

| Suitable for repeated opening and closing |

The flap capacity is optional for this closure style.

Threaded Ribbon Tie

The presence of a flap reinforcement depends on the bag size and the intended load. A second layer on the flap makes the bag a more upscale design solution.

This closure is great for the bag with no handle or used together with the single rope and ribbon handle style.

There are no limits to the flap outline. The flap height is determined by the technological requirements for the distance between the ribbon slots and the creases.

| Тypically used for disposable packaging |

| Optional tear strip and perforation |

| Suitable for one-time opening and closing |

Adhesive Tape

The presence of a flap capacity is not recommended for this closure style.

It is typically used on flaps with no flap reinforcement.

The adhesive tape closure combines with the bag with no handle. The die-cut handle style is also applicable.

The flap shape and height depend on the bag’s purpose. A tear strip and perforation plus double peel-and-seal adhesive stripes are used on e-commerce paper mailer bags with larger flaps.

| Variable velcro shape, colour & strength |

| Doesn’t interfere with the bag’s artwork |

| Suitable for repeated opening and closing |

Velcro

The presence of a flap capacity is optional for this closure style.

The flap reinforcement makes the bag more luxurious. The presence of a flap reinforcement depends on the bag size and the intended load. It is recommended for large bags and heavy weights.

This closure is applicable for all handle styles, apart from the ribbon loop style.

There are no limitations considering the flap outline and height.

| Variable shape of the locking element |

| Suitable for 100% recyclable paper bags |

| Suitable for repeated opening and closing |

Tuck-Lock

This closure style is usually applied to non-capacity flaps. Only a limited variety of locking element shapes can be used with capacity flaps.

The tuck-lock requires flexibility of the flap panel. It’s typically used on flaps with no flap reinforcement.

The tuck-lock combines beautifully with the die-cut handle style, or with a flap bag with no handle.

Any kind of flap outline and height is applicable. Small-size bags are more suitable for this closing style.

| Satin and grosgrain ribbon styles |

| Customisable ribbon length |

| Suitable for repeated opening and closing |

The flap capacity is optional for this closure style.

Threaded Ribbon Tie

The presence of a flap reinforcement depends on the bag size and the intended load. A second layer on the flap makes the bag a more upscale design solution.

This closure is great for the bag with no handle or used together with the single rope and ribbon handle style.

There are no limits to the flap outline. The flap height is determined by the technological requirements for the distance between the ribbon slots and the creases.

| Тypically used for disposable packaging |

| Optional tear strip and perforation |

| Suitable for one-time opening and closing |

Adhesive Tape

The presence of a flap capacity is not recommended for this closure style.

It is typically used on flaps with no flap reinforcement.

The adhesive tape closure combines with the bag with no handle. The die-cut handle style is also applicable.

The flap shape and height depend on the bag’s purpose. A tear strip and perforation plus double peel-and-seal adhesive stripes are used on e-commerce paper mailer bags with larger flaps.

Flap Shape

The custom-cut flap is a powerful tool to enhance brand recognition. Specially designed dielines can follow signature artwork elements for an upscale design. The possible shapes are not limited to the examples below.

Inside look at real-life projects

Are you inspired by the Artistic Flap Bag?

Let’s discuss your packaging concept.

We will go together through all details and will help you to make the best choices for your project.

Project Brief

1.

PROJECT OUTLINE

We highlight the purpose and key elements of the packaging project. We start a discussion about product type, sizes, colours, materials, branding methods and more.

INITIAL QUOTING

Based on project specifics in combination with the established design features and quantities, we quote exact unit cost or а rough price range and all one-time expenses.

Sustainability Management

We transparently share choices of packaging features for a sustainable packaging product through a well-managed design and manufacturing process.

PRODUCT RECYCLABILITY

RECYCLED MATERIALS

CARBON FOOTPRINT MANAGEMENT

PAPER OFFCUTS UTILISATION

SIZE AND DESIGN OPTIMISATION