The Fuel Can – Custom Themed Paper Bag

CREATIVE EVENT BAG DESIGN IDEA

Although this is not a recent project, we have decided to share its story with you for two main reasons:

- This exclusive paper bag is likely to be seen elsewhere on the internet. Still, it was created by the nPack team and it belongs right here.

- It is the symbolic start of our creative process that began almost 12 years ago.

The invention of structural design elements with irregular shapes that match image outlines

Back in 2011, our partner approached us for a very special project. For an upcoming charity event for oldtimer car owners, the event planners wanted a gift bag that spoke about the theme without words.

HOW THIS PROJECT BEGAN

What’s better for a car-themed event than a fuel-can-shaped paper bag?

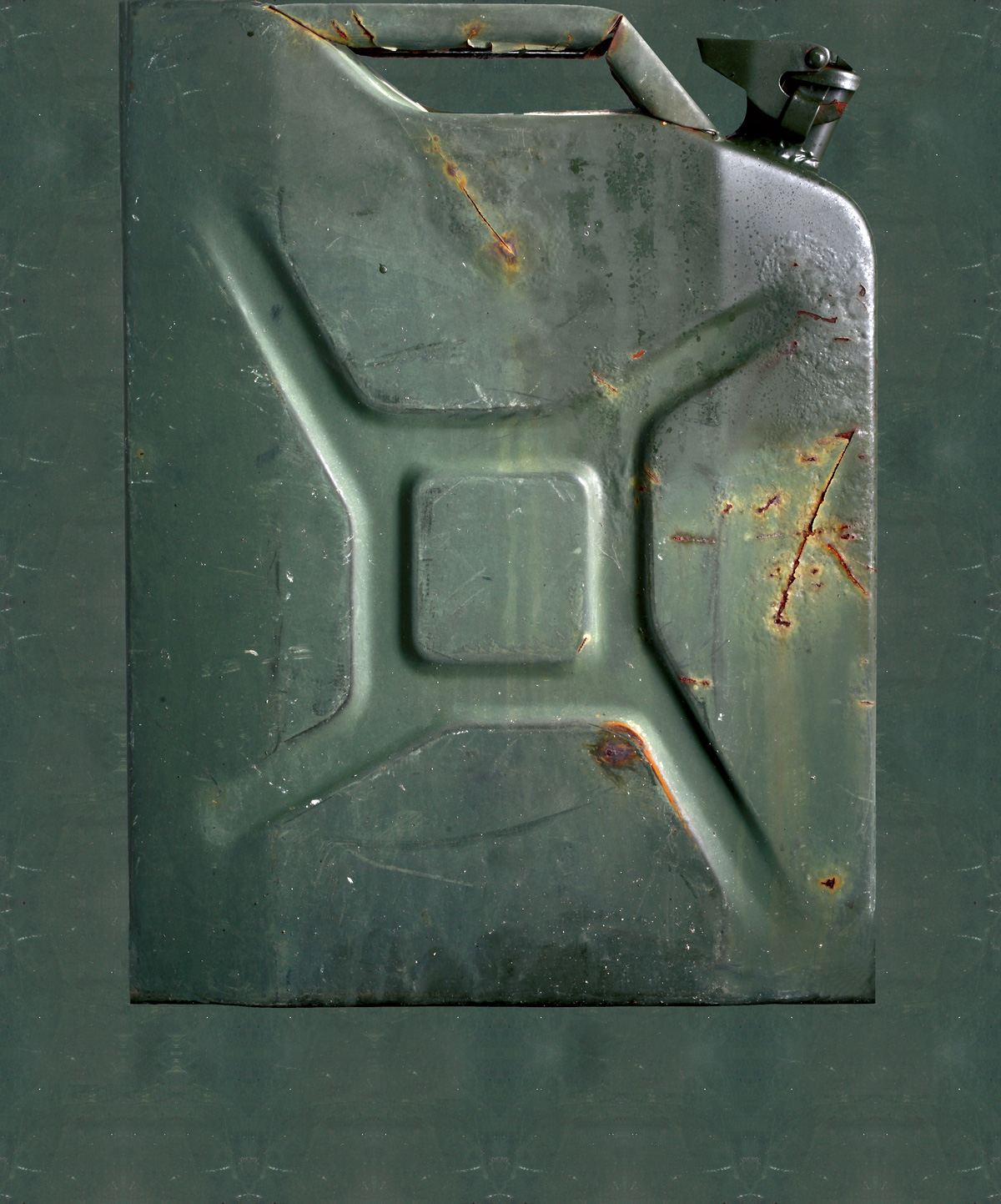

Our client had chosen a stock image of a rusty can from the internet and wanted it printed on a bag, all over.

In addition, the bag outline had to follow the outline of the can, including the cap and the handle.

An open-minded, experienced manufacturer was the one that could complete this kind of project.

We accepted the challenge and our partner trusted us with the whole concept. Our team developed the gas can bag from laminated paperboard printed in full colour and embossed with the event logo.

We worked on:

Exterior design

Tailored production

Step by step

PRODUCT DEVELOPMENT

We designed the cuts and creases in a way that followed the specific outlines of the fuel can in great detail. The artwork was adapted to cover the surface on the inside and outside.

DESIGN VERIFICATION

Using a prototype., we tested the die-cut handle strength and all the reinforcements. During a simulation, we used the actual weight of the goodies that our client informed us about.

MANUFACTURING

The manufacturing process involved special operations during the assembly. Extra reinforcements with exact placement required mastery and exclusive supervision.

Working on the realistic appearance

Having an image of the can front only, was nowhere near the ideal starting point. It didn’t fit the standard bag shape and it didn’t give us the sides and the bottom of the can.

CUSTOM CUT

The beauty of this project is that the cutting line follows specific details in the artwork.

Our product development team was delighted by the task.

Trusting our industry knowledge, we chose the proper handle size and position in combination with the image’s particular features.

Following came the cap. We made it in reduced detail, not losing the typical outline but avoiding all the little hooky parts that could be bent easily.

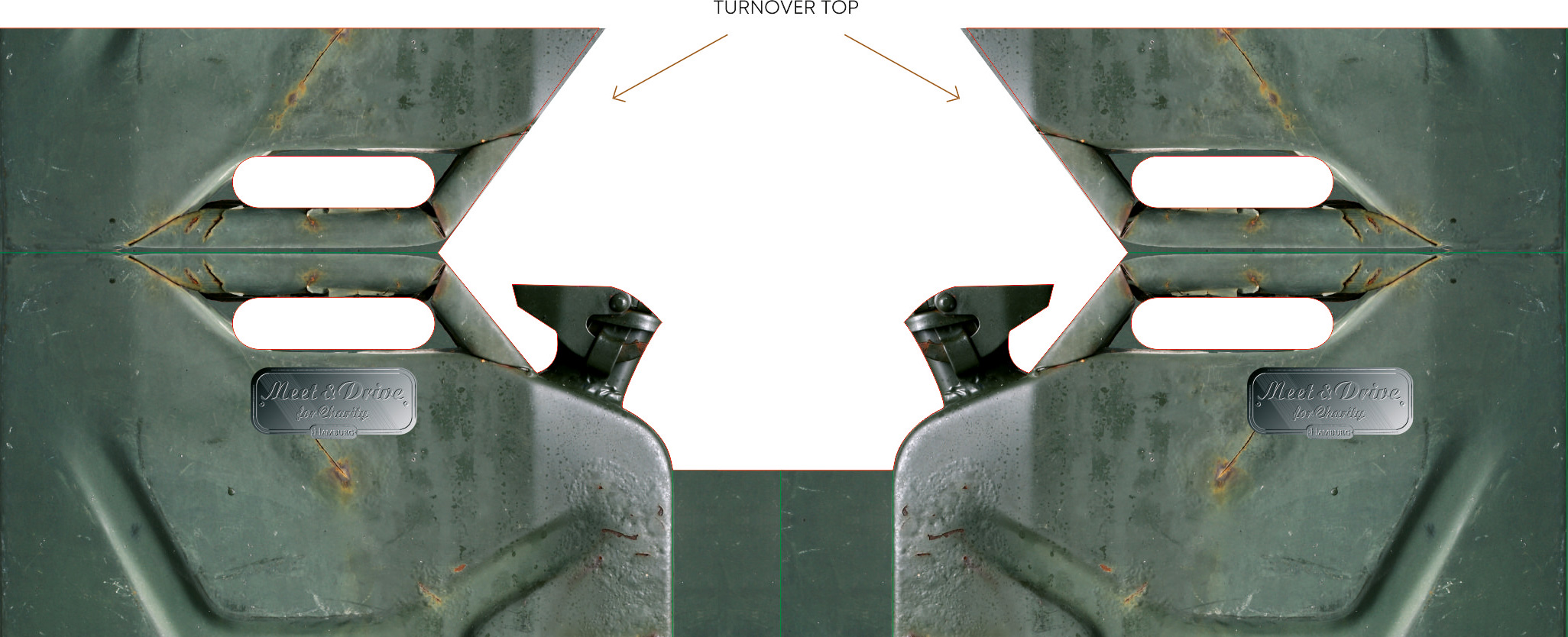

The ready bag has mirroring faces, with grip holes centred to create the ideal balance.

ARTWORK ADAPTATION

We had the task to complete the picture with the appearance of the panels that were absent in the original photo.

Then, we created a pattern for the missing parts – the narrow sides and the bottom and also turned the rounded corners into straight ones.

We repeated the design over the turnover top. After cutting, the print would give the rusty look of the handle’s inner side, too.

We had all the outer surfaces covered.

The event nameplate ‘Meet & Drive’ was included in the print and embossed. The overrall impression of a realistic can was completed by adding a matt lamination finish on the outside.

Achieving perfection via multi-stage assembly

The fuel can bag was our first project where we started to develop the exclusive manufacturing technology of custom-shaped bags. This technology underlies the development of all our subsequent creative design projects.

A considerable weight had to go into the bag, so we couldn’t compromise the handle’s strength and rigidity. Usually, the reinforcements are regular, rectangular pieces, but not in this case. Using special-shaped reinforcement led to the adaptation of the manufacturing process. As a result, it involved additional printing and an intermediate stage of die-cutting for the reinforcement.

To add to the visual impact of the bag, the inside was flood-printed in forest green colour.

The same green colour was used on the reinforcements to avoid unappealing contrast.

Inside flood print alternated with blank areas that marked the reinforcement positions. They were left inkless for better adhesion of the paperboard layer.

All parts stuck together impeccably.

The reliability of the result of our bespoke manufacturing process passed tests during a pre-production design verification stage. In due time, a series of tests were performed with prototypes and pilot copies from the order run.

Our fuel can bag, also known as the gas can bag, was a very successful concept. Through the years, the following events used it too. In effect, we produced it repeatedly, in thousands of copies.

This bag was included in the Packaging of the World’s selection of ‘Featured commercial work’ under the ‘Special-shaped die-cut category’*.

*For more information, please visit Packaging of the World, one of the world’s leading packaging design platforms on the internet, https://www.packagingoftheworld.com/

Are you inspired by our work?

Let’s discuss your packaging concept.

We will go together through all details and will help you to make the best choices for your project.

Design with confidence

Discover more case studies

Get closer to our everyday work through a collection of projects showcasing nPack’s contribution to the amazing world of luxury packaging.