Luxury Folder Box

A BOOK-STYLE BOX AS CREATIVE STATIONERY

Product styles / Luxury folder box

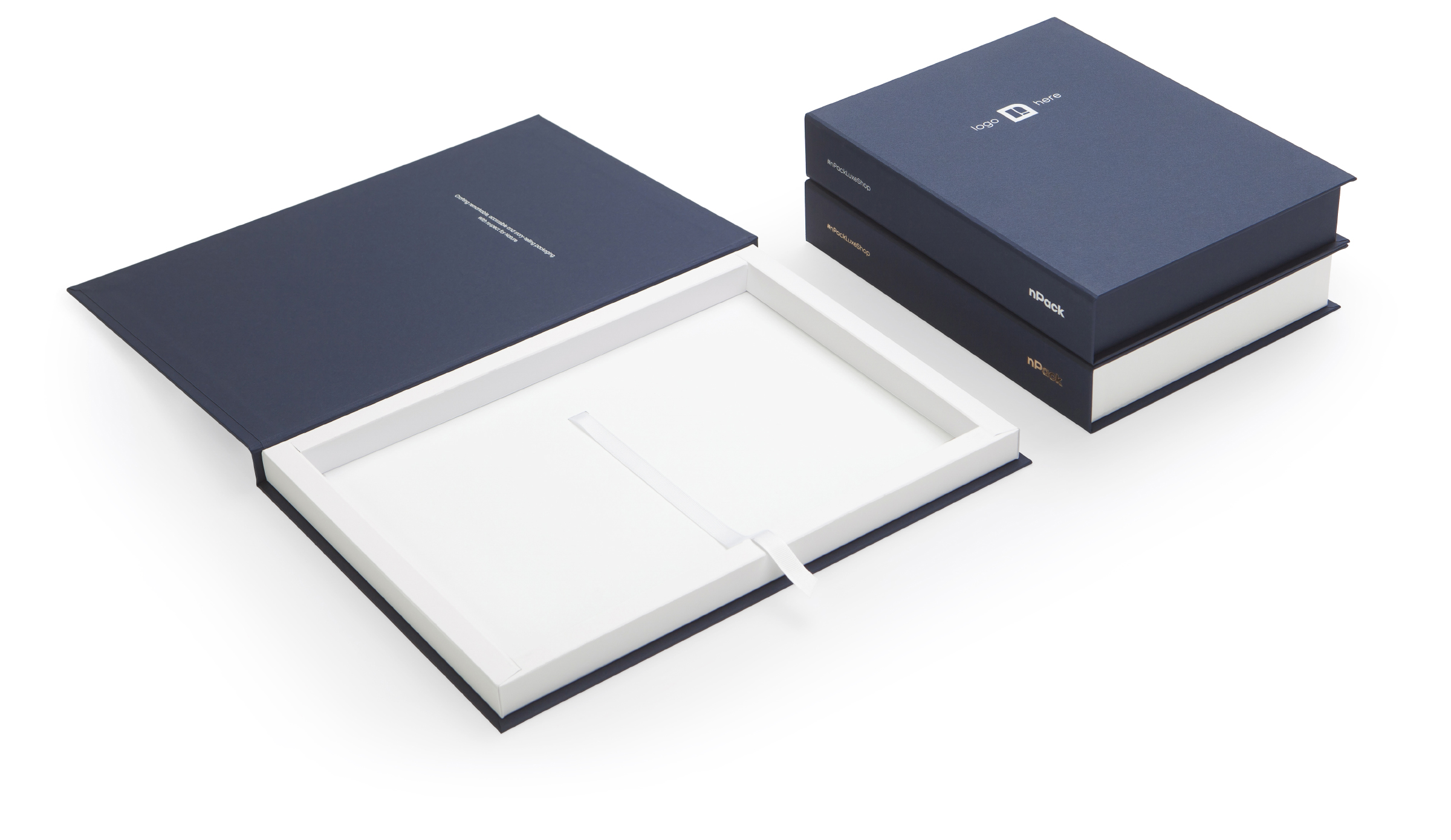

Impressive presentation box packaging

The luxury folder box is a representative of the book-style boxes with a frame tray. We make it with custom dimensions but most often in A5+, A4+ and even A3+ sizes to fit any type of printed materials.

The tray’s style is suitable for containing lightweight inserts from paper and paperboard that offer a platform and a mounting position for cards, certificates, leaflets and other printed items. Specially designed paper elements are typically chosen during the product development of this creative presentation box packaging.

CUSTOMISATION OPTIONS

Box style options

MAGNETIC SIDE ORIENTATION

Portrait or Landscape

INTERIOR LEVEL

With or without a level platform

RIBBON LIFT

Loose-end or loop ribbon

MOUNTING SLOTS & CORNERS

Custom number and shape

CARD POCKET

Plastic or paper

Detailed info below:

Box Anatomy; Design Options

MINIMUM ORDER – 100 PCS

Sizes, materials & finishes

SIZES

Variety of stock cutters or custom size by request

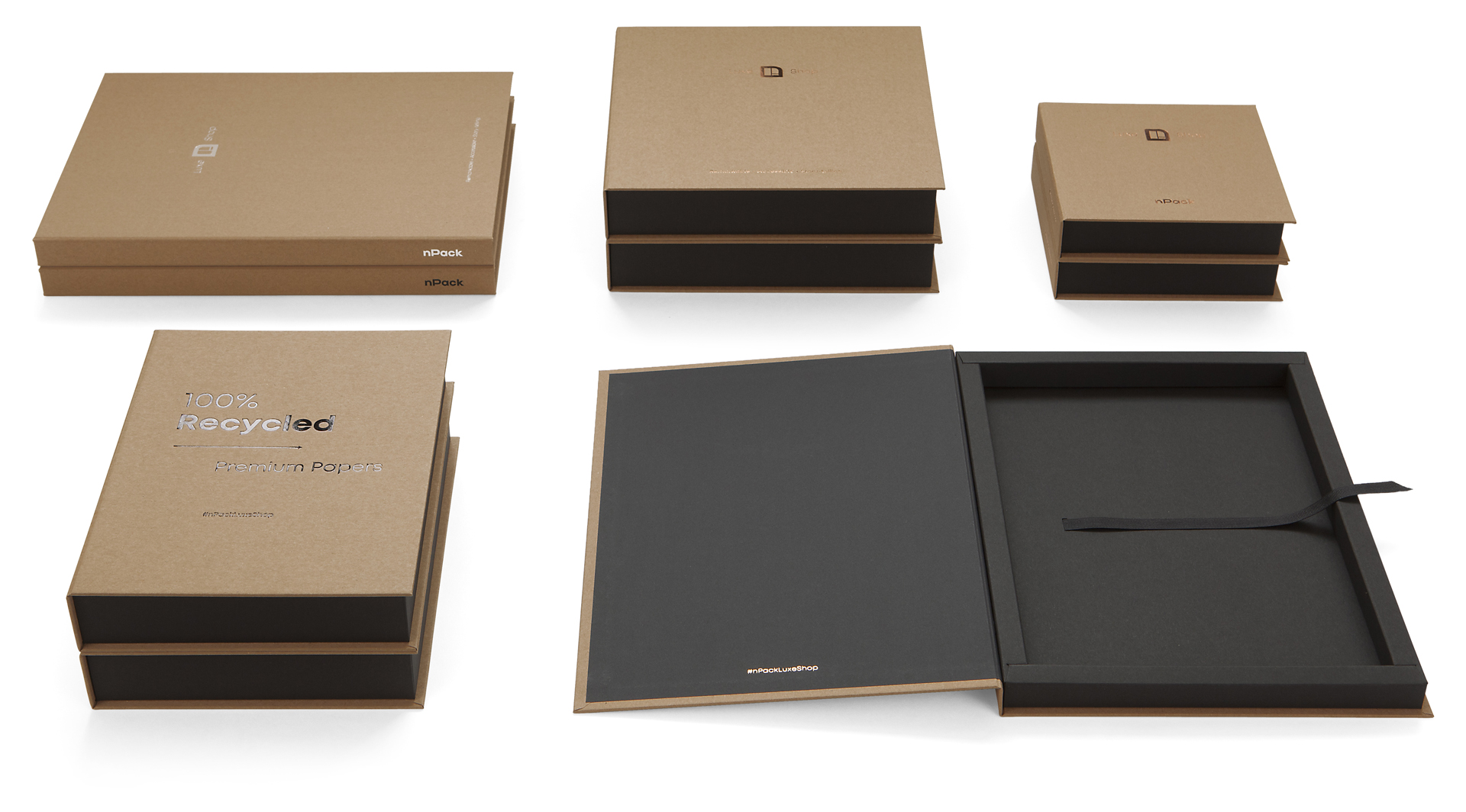

PREMIUM PAPERS

White or colour-dyed papers made in Europe, smooth or textured in different patterns

PRINTING OPTIONS

CMYK or Pantone printing for exact colour match

LUXURY FINISHES

Foil blocking, foil embossing, foil debossing, blind embossing, blind debossing or spot UV

COATING

Matt, gloss or soft touch lamination

1300 +

STOCK SIZE CUTTERS

AVAILABLE

60 +

DESIGN ELEMENTS READY FOR

PRODUCTION

100 +

PREMIUM PAPERS IN

PRODUCTION

Structural elements

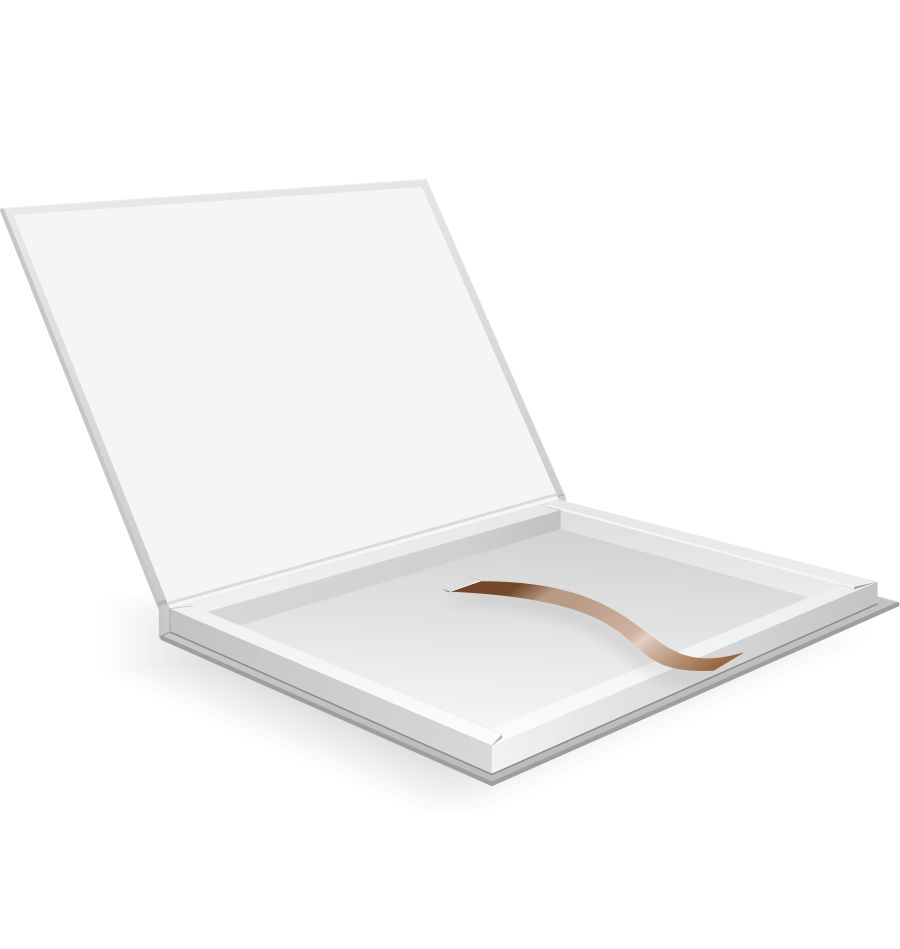

The basic, constant elements of the luxury presentation folder box style are the frame tray and the 3-panel hard cover. The recommended closure style is magnetic closure.

The luxury folder can be made with portrait or landscape orientation based on the magnet placement on the long or short side. The cover’s spine can be glued to the tray, or it may remain unglued to lay flat.

Hard Cover

The 3 panels have a greyboard core covered with a binding material.

Most often, the greyboard is 2 mm thick, but the thickness may vary according to the client’s request.

The binding material is typically thin paper and the possible paper options are endless.

Frame Tray

The tray is made from thick paperboard with a weight of ca. 300-350 gsm.

The recommended frame tray depth is 15 to 30 mm.

Reinforcement

Inside the hollow wall opposite to the spine we glue a hidden 2 mm greyboard reinforcement which makes the box as reliable as any rigid box.

The luxury folder can be made with portrait or landscape orientation based on the magnet placement on the long or short side. The cover’s spine can be glued to the tray, or it may remain unglued to lay flat.

Hard Cover

The 3 panels have a greyboard core covered with a binding material.

Most often, the greyboard is 2 mm thick, but the thickness may vary according to the client’s request.

The binding material is typically thin paper and the possible paper options are endless.

Frame Tray

The tray is made from thick paperboard with a weight of ca. 300-350 gsm.

The recommended frame tray depth is 15 to 30 mm.

Reinforcement

Inside the hollow wall opposite to the spine we glue a hidden 2 mm greyboard reinforcement which makes the box as reliable as any rigid box.

Make it remarkable

nPack’s inventive team has designed some additional, optional details to enhance the luxury folder. These details add even more appeal to the box appearance and have extra functions for ease of use and fixture of card-shaped elements. Such details are the interior level, the ribbon lifts, mounting slots and corners and card pockets.

Interior Level

The interior level is a platform which fits tightly inside the frame tray. It brings the product upwards toward the top of the tray for easier reach and better visibility. It can be removable or glued to the tray according to technical requirements.

The interior level platform is a sustainable box insert.

It is made from thick paper or paperboard. It often uses offcuts from the tray’s production.

The level depth is customisable.

Optionally, a hidden reinforcement can be added under the level for a more solid and luxurious feel.

Ribbon Lift

This optional element consists of a single ribbon, permanently glued to the box bottom or to the level platform. It helps to take out the box contents without effort. The lifts come in two styles, using a loose-end ribbon or a ribbon loop.

Loose-End Ribbon

This style is applicable for long ribbons that are glued at a great distance from the opening side of the box.

The length of the ribbon piece varies according to the box size and the client’s requirements. The ribbon width that we recommend is 10 mm.

Satin and grosgrain ribbons are the best applicable ribbon styles for their non-fraying hot-processed loose end.

Loose-End Ribbon

This style is applicable for long ribbons that are glued at a great distance from the opening side of the box.

The length of the ribbon piece varies according to the box size and the client’s requirements. The ribbon width that we recommend is 10 mm.

Satin and grosgrain ribbons are the best applicable ribbon styles for their non-fraying hot-processed loose end.

Mounting Slots

Mounting slots are applicable together with the interior level platform, to stop the printed material from moving inside the box.

Mounting Corners

The mounting corner set consists of four elements permanently attached to the box. They can be situated on the hard cover inside or on the interior level platform. Typically, their purpose is to hold cards or envelopes.

Card Pocket

The card pocket is an additional piece glued to the hard cover inside. Its general function is to hold a business card, a greeting card or a gift card. The pockets can be made from plastic or paper.

Plastic pocket

The most common material for the plastic pocket is clear foil. These pockets are stock items from trusted suppliers and come with horizontal or vertical orientation.

The pocket size depends on the country’s business card and plastic card standards.

Paper Pocket

Using a more sustainable approach, the card pocket can be made from paper with various thickness possibilities.

Paper pockets are made to order and their shapes and sizes are customisable.

Plastic pocket

The most common material for the plastic pocket is clear foil. These pockets are stock items from trusted suppliers and come with horizontal or vertical orientation.

The pocket size depends on the country’s business card and plastic card standards.

Paper Pocket

Using a more sustainable approach, the card pocket can be made from paper with various thickness possibilities.

Paper pockets are made to order and their shapes and sizes are customisable.

Inside look at our favourites

Are you inspired by the Luxury Folder Box?

Let’s discuss your packaging concept.

We will go together through all details and will help you to make the best choices for your project.

Project Brief

1.

PROJECT OUTLINE

We highlight the purpose and key elements of the packaging project. We start a discussion about product type, sizes, colours, materials, branding methods and more.

INITIAL QUOTING

Based on project specifics in combination with the established design features and quantities, we quote exact unit cost or а rough price range and all one-time expenses.

Sustainability Management

We transparently share choices of packaging features for a sustainable packaging product through a well-managed design and manufacturing process.

PRODUCT RECYCLABILITY

RECYCLED MATERIALS

CARBON FOOTPRINT MANAGEMENT

PAPER OFFCUTS UTILISATION

SIZE AND DESIGN OPTIMISATION