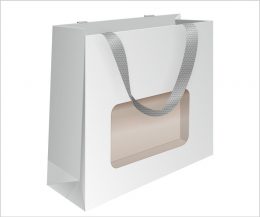

Paper Ribbon Handle Bag

ECO-FRIENDLY LUXURY PAPER BAG WITH RECYCLABLE HANDLES

Luxury Paper Bags / Paper ribbon handle bag

A valid statement of sustainability awareness

The paper bag with paper ribbon handles is the luxury bag style that has zero plastic ingredients in the handle material.

Due to the specific handle weaving, this bag style has the classic luxury appearance of a premium paper bag. At the same time, it corresponds to nPack’s understanding of the eco-friendly and positive impact on the environment.

CUSTOMISATION OPTIONS

Bag style options

HANDLE ATTACHMENT

Glued

RIBBON STYLE

Knitted or braided

DESIGN UPGRADES

Ribbon closure, hang tags, custom bag body elements and extra handles

Detailed info below:

Bag Anatomy; Design Upgrades

MINIMUM ORDER – 100 PCS

Sizes, materials & finishes

SIZES

Variety of stock cutters or custom size by request

PREMIUM PAPERS

White or colour-dyed papers made in Europe, smooth or textured in different patterns

PRINTING OPTIONS

CMYK or Pantone printing for exact colour match

LUXURY FINISHES

Foil blocking, foil embossing, foil debossing, blind embossing, blind debossing or spot UV

COATING

Matt, gloss or soft touch lamination

Share more about your project

Please note, your current choices will be saved if you close the window to review the options.

1300 +

STOCK SIZE CUTTERS

AVAILABLE

60 +

DESIGN ELEMENTS READY FOR

PRODUCTION

100 +

PREMIUM PAPERS IN

PRODUCTION

Structural elements

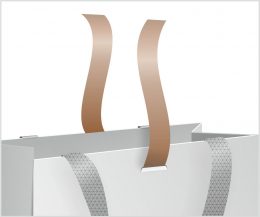

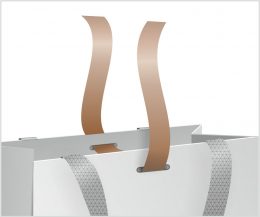

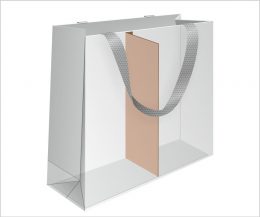

The standard, rectangular body shape of the luxury paper bag, with its reinforced turn-over top, is perfectly suited for flat paper handles. Two optional weaving styles are available.

The handles are attached permanently to the bag body. The most trusted handle attachment for the eco-friendly paper ribbon is carried out via glueing.

The ribbon ends are discreetly hidden and glued strongly under the turnover top and come out through delicate slots.

Bag body materials

The bag body is made from paper or paperboard. The material thickness is usually around 200 to 300 g/sq.m.

Reinforcement

To increase the bag’s strength and reliability, we add reinforcing layers. They are placed on the inside of the bag’s bottom and under the turnover top. The reinforcing layers are permanently glued to the body material.

All reinforcing bottom pieces have a thickness of at least 350 g/sq.m. The TOT reinforcement is ca. 700 g/sq.m. per side. This extra support adds to the bag’s high-quality standard.

Handles

In all cases, the paper handles are attached to the bag body permanently by glueing. The ribbon ends are discreetly hidden under the turnover top and come out through delicate slots.

The ribbon ends are discreetly hidden and glued strongly under the turnover top and come out through delicate slots.

Bag body materials

The bag body is made from paper or paperboard. The material thickness is usually around 200 to 300 g/sq.m.

Reinforcement

To increase the bag’s strength and reliability, we add reinforcing layers. They are placed on the inside of the bag’s bottom and under the turnover top. The reinforcing layers are permanently glued to the body material.

All reinforcing bottom pieces have a thickness of at least 350 g/sq.m. The TOT reinforcement is ca. 700 g/sq.m. per side. This extra support adds to the bag’s high-quality standard.

Handles

In all cases, the paper handles are attached to the bag body permanently by glueing. The ribbon ends are discreetly hidden under the turnover top and come out through delicate slots.

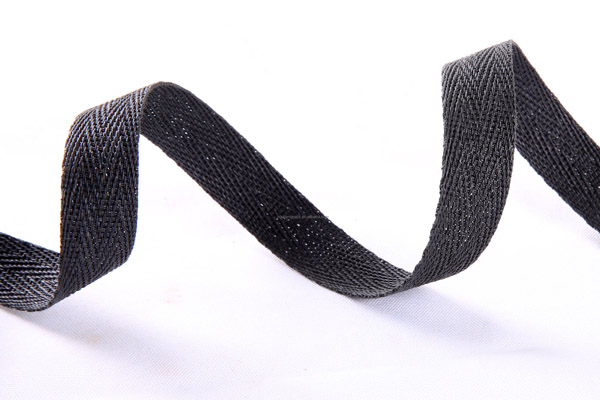

Ribbon Style

These handles are entirely made from paper and have different thicknesses depending on the chosen style. The ribbon width that we typically use is 20 mm. The length depends on the bag size and the client’s preference. There are some basic colours in stock and others are available after a custom order.

A basic paper bag with special handles made from recyclable materials all over

Make it remarkable

The bag upgrades are packaging design elements for extra functionality, custom inner shape or new capacity. Each of them presents a great opportunity to create tailored packaging solutions.

Ribbon Closure

Ribbons are used as an elegant finishing touch to the paper bag. They have a double purpose – to decorate and to serve as closure. Ribbons are available in different widths and lengths, dozens of colours and various materials.

The central ribbon has two attachment styles, glued or threaded. Design tips

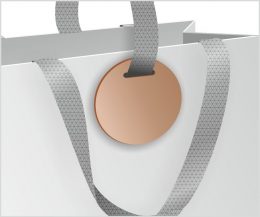

Swing Tags

The swing tags are additional cardboard elements that hang on a thin string. The tags may have custom shapes and the strings come in different styles.

There are three possible attachment positions: on the handle, on the bag body or on the turnover top. Design tips

Fixed Tags

The fixed tags are cardboard elements that have a punched hole or a slot large enough to fit a threaded rope or a ribbon.

This type of tag is suitable for fixing either on the ribbon closure. Design tips

Bag Body Elements

These options add to the bag’s appeal and bring its functionality to a new level.

These elements have different customisable design features, such as the contrasting inlay colour and texture, the clear window outline or the separator’s style and attachment. Design tips

Extra Handles

In addition to the basic bag handle, die-cut handle slots may be present to form a combined handle design.

The extra handles add an alternative way of carrying the paper bag. The die-cut grip hole shape is customisable. Design tips

More upgrade options can be specially developed and produced for specific product and brand requirements.

Achieve 100% recyclability

Are you interested in a similar product?

Share the project specifics and product features you are considering and we will come back to you with comments and price options.

Share more about your project

Please note, your current choices will be saved if you close the window to review the options.

Project Brief

1.

PROJECT OUTLINE

We highlight the purpose and key elements of the packaging project. We start a discussion about product type, sizes, colours, materials, branding methods and more.

INITIAL QUOTING

Based on project specifics in combination with the established design features and quantities, we quote exact unit cost or а rough price range and all one-time expenses.

Sustainability Management

We transparently share choices of packaging features for a sustainable packaging product through a well-managed design and manufacturing process.

PRODUCT RECYCLABILITY

RECYCLED MATERIALS

CARBON FOOTPRINT MANAGEMENT

PAPER OFFCUTS UTILISATION

SIZE AND DESIGN OPTIMISATION