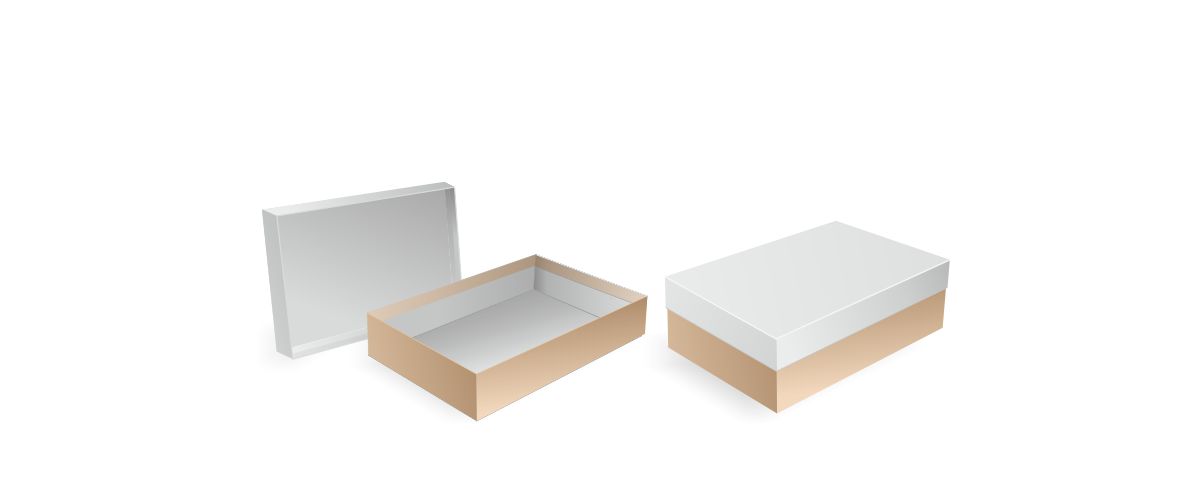

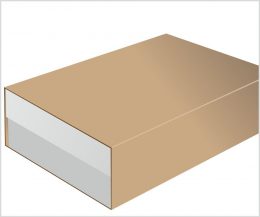

Lid And Base Box

2-PIECE TAILOR-MADE ECO-FRIENDLY BOX

Luxury rigid boxes / Lid and base box

A widely loved version of luxury packaging

This historic box is a classic model consisting of a rigid tray with a removable, lift-off lid. Due to the lack of magnets and with the choice of unlaminated paper, the box can be 100% recyclable. The construction is very durable and sturdy. It is a preferred style for a high-end mailing box, carrying a brand’s name for practically unlimited time.

CUSTOMISATION OPTIONS

Box style options

LID FITTING

Tight or loose lid

LID DEPTH

Full-height, partial-height or light-weight lid

DESIGN UPGRADES

Ribbons, tray inserts, pockets, sleeves and custom developed elements

Detailed info below:

Box Anatomy; Design Upgrades

MINIMUM ORDER – 100 PCS

Sizes, materials & finishes

SIZES

Variety of stock cutters or custom size by request

PREMIUM PAPERS

White or colour-dyed papers made in Europe, smooth or textured in different patterns

PRINTING OPTIONS

CMYK or Pantone printing for exact colour match

LUXURY FINISHES

Foil blocking, foil embossing or spot UV

COATING

Matt, gloss or soft touch lamination

Share more about your project

Please note, your current choices will be saved if you close the window to review the options.

1300 +

STOCK SIZE CUTTERS

AVAILABLE

60 +

DESIGN ELEMENTS READY FOR

PRODUCTION

100 +

PREMIUM PAPERS IN

PRODUCTION

Structural elements

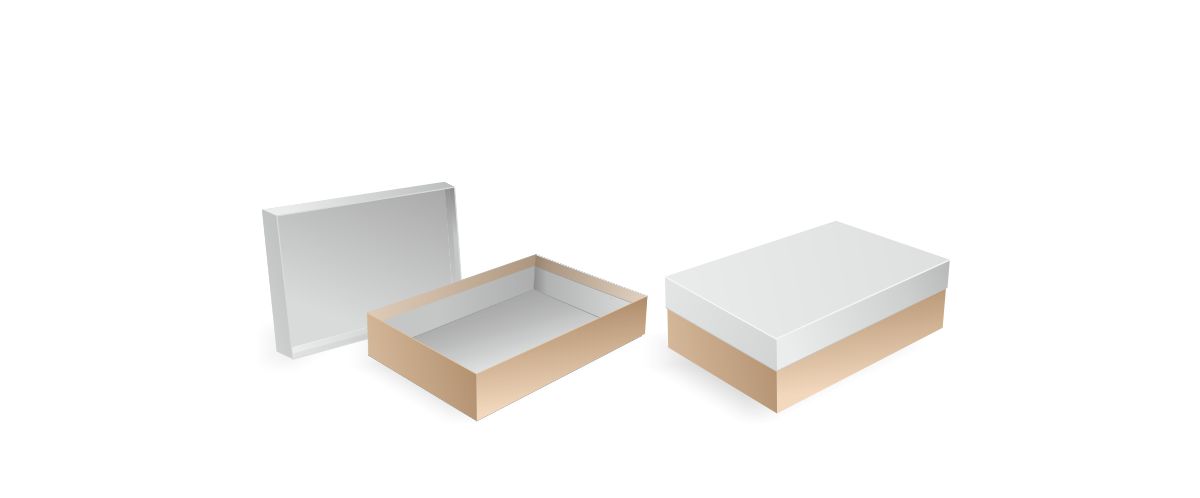

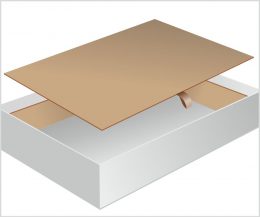

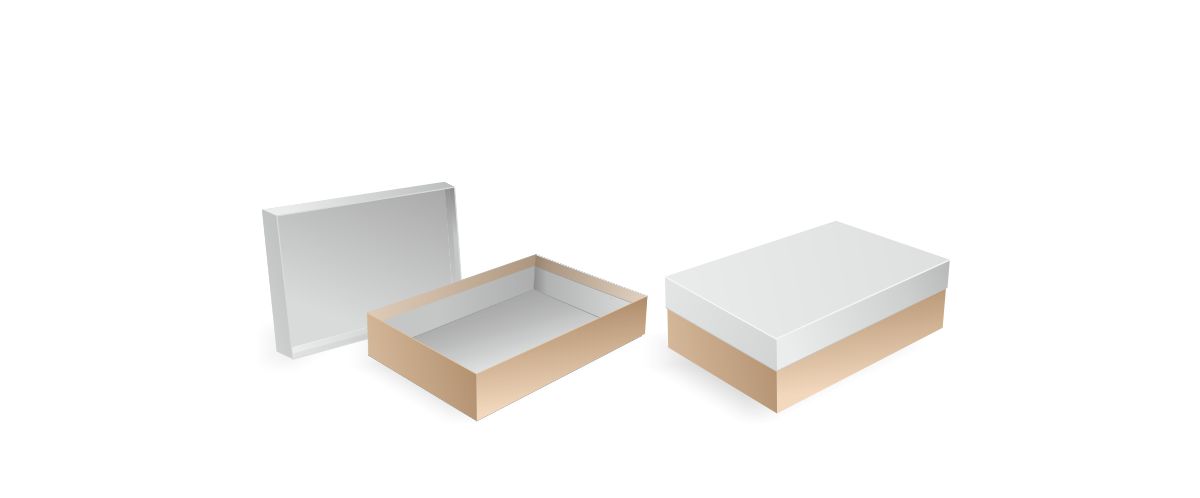

The lid and base box is a telescopic model in which the lid fits over the base, where the base is the narrower part. The lid can be as large as needed to either come off easily or to encase the base tightly. With the tight fit of the lid, also known as vacuum fit, two hands take part to open the box. If the fit of the lid is loose, you can open the box one-handed, the bottom will remain in place and the lid will go up.

The tight fit is not suitable for full-depth lids.

The loose fit lid is quick and easy to open.

Materials

All elements have a greyboard core and are covered with a binding material.

Most often, the greyboard is 2 mm thick, but the thickness may vary according to the client’s request. The binding material is typically thin paper.

The binding material is typically thin paper.

The tight fit is not suitable for full-depth lids.

The loose fit lid is quick and easy to open.

Materials

All elements have a greyboard core and are covered with a binding material.

Most often, the greyboard is 2 mm thick, but the thickness may vary according to the client’s request. The binding material is typically thin paper.

The binding material is typically thin paper.

Lid Depth

There are three different variants of the lid depth, all of them good looking but with different purposes. This detail can be discussed and taken into account during the project brief step of the process at the beginning of our project.

The lid is the same height as the base. When the box is closed, the base isn’t showing and the lid goes all the way down the box sides.

The lid partially covers the base. On the closed box, the lower part of the base is exposed and becomes useful to grip if the lid fits tight.

The lid has minimal depth, similar to a shoebox. It only covers a small portion of the base. This makes the box much lighter in weight.

The lid & base style becomes the best luxury mailing box for its durability and shipping resistance

Make it remarkable

The box upgrades are packaging design elements for extra functionality, custom inner shape or new capacity. Each of them presents a great opportunity to create tailored packaging solutions.

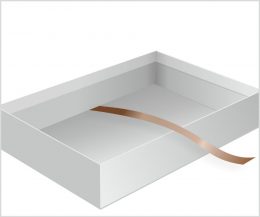

Ribbons

Delicate flat ribbons are a great embellishment to the luxury box. They come in a great variety and are available in different widths and lengths, colours and materials.

The ribbons are easy-to-use pulls and add to the box appeal and to the unboxing experience. For our Lid & Base boxes, we offer ribbon lifts for comfortable extraction of the box contents. Design tips

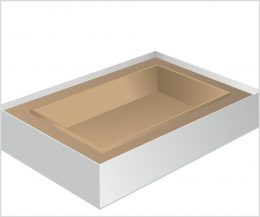

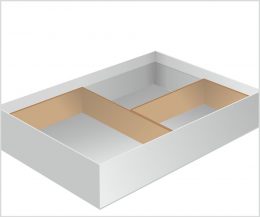

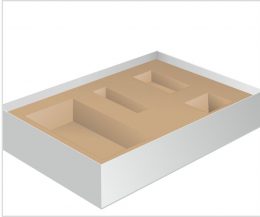

Tray Inserts

The tray inserts are custom elements made from paper and solidboard. They create custom inner shapes or change the tray capacity.

All the extra inserts are instruments for a greater unboxing experience. They can be used separately or in combination. The interior tray and interior lid are packaging solutions pre-designed by nPack’s team and customisable in size and appearance. Dividers and custom inlays are developed according to clients’ projects. Design tips

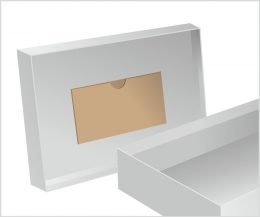

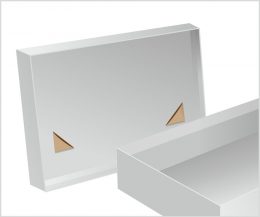

Pockets

All pockets provided by nPack are box elements made from paper and solidboard. They are suitable for flat paper sheets, such as documents and certificates, or for any type of card. The paper wallets serve as envelopes while the mounting corners fix an envelope to the box lid. Typically, the pockets are glued to an exact place on the box according to clients’ needs. Design tips

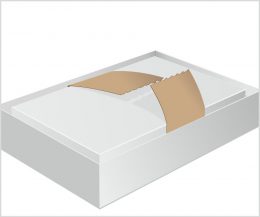

Sleeves

The sleeves are partial box wrappers opened at two ends.

The outer sleeve and the banderole are used as means of fixing the box closed, or just for the purpose of adding an extra printable surface. The lift-off band is a specially developed sleeve which uses a tear-off strip which turns it into a handle to take out one box from another box. Design tips

More upgrade options can be specially developed and produced for specific product and brand requirements.

Inside look at real-life projects

Are you interested in a similar product?

Share the project specifics and product features you are considering and we will come back to you with comments and price options.

Share more about your project

Please note, your current choices will be saved if you close the window to review the options.

Project Brief

1.

PROJECT OUTLINE

We highlight the purpose and key elements of the packaging project. We start a discussion about product type, sizes, colours, materials, branding methods and more.

INITIAL QUOTING

Based on project specifics in combination with the established design features and quantities, we quote exact unit cost or а rough price range and all one-time expenses.

Sustainability Management

We transparently share choices of packaging features for a sustainable packaging product through a well-managed design and manufacturing process.

PRODUCT RECYCLABILITY

RECYCLED MATERIALS

CARBON FOOTPRINT MANAGEMENT

PAPER OFFCUTS UTILISATION

SIZE AND DESIGN OPTIMISATION